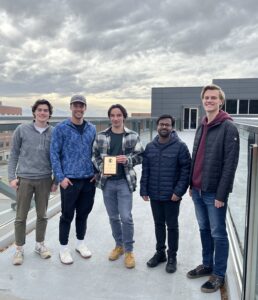

A team of graduate students from the University of Utah Department of Mechanical Engineering and Dr. Michael Czabaj’s Utah Composites Lab took first place in the American Society for Composites (ASC) Student Simulation Challenge at this year’s technical conference. Students Connor Farrel, Erik Langlo, Garrett Mackay, Vignesh Rao, and Andrew Westerhoff worked together to complete three tasks that combined finite element (FE) simulations of fracture in a composite laminate with a machine learning model optimizer to predict certain input parameters for the FE simulation.

A team of graduate students from the University of Utah Department of Mechanical Engineering and Dr. Michael Czabaj’s Utah Composites Lab took first place in the American Society for Composites (ASC) Student Simulation Challenge at this year’s technical conference. Students Connor Farrel, Erik Langlo, Garrett Mackay, Vignesh Rao, and Andrew Westerhoff worked together to complete three tasks that combined finite element (FE) simulations of fracture in a composite laminate with a machine learning model optimizer to predict certain input parameters for the FE simulation.

First, the students were asked to build an FE model of the test and match it with published benchmark model results. The second task focused on running the model with different input material parameters to train a machine learning model to predict the load-displacement curves for a given set of input parameters with a goal of getting reasonable predictions compared to the model. For the last task, the students optimized the model to do a reverse prediction of task 2, providing the load-displacement curve and seeing if it could predict the input parameters.

“We focused on task one first, since we knew the model had to be accurate and fast to give us a chance of getting good results for the second and third tasks,” said Farrell. “We started with three different modeling approaches that we had used before in our research. From these models we were able to pick the one that matched the benchmark data the best and was most efficient to run.”

Once the students had their model running fast, Rao helped them pick a strategy for the machine learning piece. They went with an artificial neural network because of its ability to approximate any continuous function. After training the model to match the FE results accurately, they used a genetic algorithm optimizer for the final task. They chose this because it works well for optimization problems involving large search spaces while avoiding local minima.

“A few of us had experience with this type of FE model in our own research, just with different test configurations,” said Farrell. “This made the first task straightforward and set us up well for the rest of the project. Vignesh, from Dr. Spear’s group, had a lot of experience with machine learning models, which really helped with the second and third tasks. We also found a good method for breaking down the load-displacement data into piecewise functions, which helped a lot with

training the model and getting good results from the optimizer. It was cool to see how we could take the FE models that we had a lot of experience and expand on them with machine learning.”

In addition to their work on the challenge, Farrell, Langlo, and Mackay presented on their research at the conference. You can find out more about the Utah Composites Lab at their website. Rao is part of the Multiscale Mechanics & Materials Lab, which you can learn more about here.