For his research proposal to explore modular magnetic mobile manipulators for microgravity environments, University of Utah mechanical engineering PhD candidate, Joseph (Joey) Brink, was selected by NASA as one of their Space Technology Research Fellows. NASA selected 65 graduate students from around the country as the 2013 class. This third class of space technology graduate students will conduct research relevant to agency technology challenges aligned with NASA’s space technology roadmaps, while pursuing degrees in related disciplines at their respective institutions.

“NASA’s space technology development and innovation pipeline sees a natural on-ramp for new ideas coming from America’s graduate researcher community,” said Michael Gazarik, NASA’s associate administrator for space technology in Washington. “By partnering with and investing in America’s brightest minds, we are guaranteeing a great future for NASA and the nation. These technology research efforts will bolster America’s competitiveness in a knowledge-based, global technology economy while enabling our space exploration goals.”

The fellows conduct innovative space technology research on their respective campuses, at NASA centers, and at nonprofit U.S. research and development laboratories. Advised by mechanical engineering assistant professor Jake Abbott, Brink responded that, “It is an honor to have been selected for a NASA fellowship. Both Prof. Abbott and I are excited to collaborate with NASA researchers on the future of magnetic manipulation in space. The Omnimagnet manipulation system, designed and developed by Andrew Petruska and Dr. Abbott in 2012, is unlike any other telerobotic manipulation technique. In microgravity, this manipulation system will relieve astronauts of both tedious routine maintenance tasks and highly dangerous extra-vehicular activity. I am looking forward to realizing the project over the next four years here at the U and at NASA research centers around the country.”

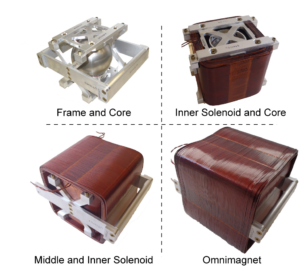

An Omnimagnet (pictured) is a cube with no moving parts. It is capable of real-time control of the magnitude and orientation of its magnetic field. If a magnetic tool is introduced in an Omnimagnet’s magnetic field, the Omnimagnet can dexterously manipulate the tool’s position and orientation, even if there is a barrier between the tool and the Omnimagnet. In space, Omnimagnets will be able to manipulate each other and their separate magnetic tools, utilizing magnetic forces and torques that go beyond simple attraction and repulsion.

By fixing to various spacecraft or satellite surfaces, Omnimagnets can “walk” across surfaces and magnetically carry tools large distances, using “inchworm” inspired approaches. Thus, Omnimagnets can deliver tools to the worksite and then manipulate those tools. Debris removal from convoluted hard-to-reach locations and assembly of structures in microgravity are some of the challenges that Omnimagnets and their tools will tackle in space.

Like other manipulation systems operating in space, such as Robonaut and SmartSPHERES, Omnimagnets will be able to relieve astronauts of both tedious routine maintenance tasks and highly dangerous extra-vehicular activity. The NASA fellowships and research activities are part of a renewed emphasis by NASA on technology. The program also is designed to inspire the nation’s students and contribute to an innovation-driven economy. For a list of fellowship recipients, their respective research institutions and research topics, visit: http://go.usa.gov/b43R.

NASA’s Space Technology Research Grants Program challenges academia to examine the theoretical feasibility of ideas and approaches that are critical to making science, space travel and exploration more effective, affordable and sustainable. The program is part of NASA’s Space Technology Mission Directorate, which is dedicated to innovating, developing, testing and flying hardware for use in NASA’s future missions. The Department of Mechanical Engineering at the University of Utah is committed to providing students with broad-based, rigorous and progressive education. By combining state-of-the-art facilities with renowned faculty, the department provides an education that gives students the necessary skills to become the next generation of innovators.