University of Utah mechanical engineering assistant professor Steven Naleway, professor Jake Abbott, and associate professor Henry Fu have received funding from the Army Research Office to research a new process to create tailored materials by combining magnetic manipulation with freeze casting. They believe this new process will allow them to create ceramic and composite engineered materials with tailored properties that fit form to function, which will have application throughout science and industry.

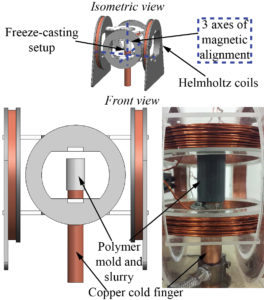

Current processing methods for these materials focus on additive manufacturing and mold-based methods. However, the structure of the engineered materials using these methods can often only be controlled on a single length scale or have poor control at multiple length scales. By contrast, the hierarchical structure of many natural materials is directly responsible for their properties. Naleway, Abbott, and Fu propose to achieve this control by combining magnetic manipulation with freeze casting.

“We want to better understand how the use of external magnetic fields can allow for tailored material structures and properties,” said Naleway. “Creating hierarchical control of the microstructure of ceramic and composite engineering materials, along with theoretical understanding of this control, will lay a strong foundation for materials fabrication and research going forward.”

Naleway and his colleagues believe this method will allow them to fabricate advanced protective materials for the Army. These materials may also be beneficial to a wide variety of applications like robotics, air and water filters, and biomedical materials.

“Hierarchical microstructures are a promising approach for increasing the performance of composite and ceramic materials,” said Dr. Michael Bakas, program manager, Army Research Office, an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory. “Professor Naleway and his colleagues can potentially establish a technical foundation for creating these microstructures that in the future will be leveraged to create new protection materials for the Army.”