Design Day

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Spring Design Day 2025

Thursday, April 17th

10am to 3pm

Union Ball Room

Saltair Room

10:30 to noon – Posters

1pm to 5pm – Robot Competition “Dune”

Senior Design Projects: Spring 2025

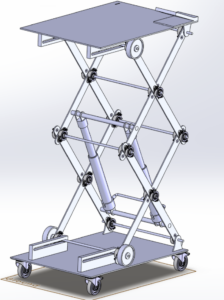

Description: Bulldozer maintenance can be difficult due to the height of areas that need repairs and the limited working area. Current methods of reaching these areas are unsafe, so maintenance technicians would like a height adjustable platform that can fit under the bulldozer and lift them up to five feet above the ground. The platform must be easily movable, feel secure while at max height, and lift any users quickly.

Team: Abby McGowan, Dominic Alei, Kalea Glaser, Sheyene Sahagun, Taiji Harada, Kellen Biehler

Advisor: A.K. Balaji

Description: Trimlight is a company that specializes in permanent lighting fixtures. Permanent lighting typically requires little to no maintenance. These lights are being damaged by electromagnetism from storms, which requires repairs. This project aims to design and implement a surge protecting device with wireless communication capabilities to preemptively disconnect electronics when a storm is overhead.

Description: Trimlight is a company that specializes in permanent lighting fixtures. Permanent lighting typically requires little to no maintenance. These lights are being damaged by electromagnetism from storms, which requires repairs. This project aims to design and implement a surge protecting device with wireless communication capabilities to preemptively disconnect electronics when a storm is overhead.

Team: John Kaiser, Faris Delgado, Jared Vazquez, Brayden Humphreys, Alex Christiansen

Advisor: Dr. Bruce Gale

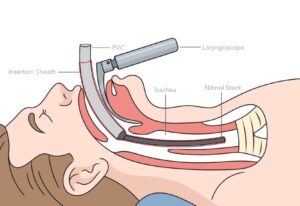

Description: Current endotracheal intubation uses a small, flexible device called a bougie and a larger, stiffer endotracheal tube. The purpose of the project is to combine a traditional intubation bougie with an endotracheal tube to create a single device that would be inserted into the throat in a compressed state, then is released into an expanded state. This will save time and minimize required devices during difficult intubations in hospitals and the field.

Description: Current endotracheal intubation uses a small, flexible device called a bougie and a larger, stiffer endotracheal tube. The purpose of the project is to combine a traditional intubation bougie with an endotracheal tube to create a single device that would be inserted into the throat in a compressed state, then is released into an expanded state. This will save time and minimize required devices during difficult intubations in hospitals and the field.

Team: MaryAnn Davis, Sydney Sestak, James Karr, Charles Bradley, Connor Blue

Advisor: Dr. Pai Wang, Dr. Jacob Hochhalter

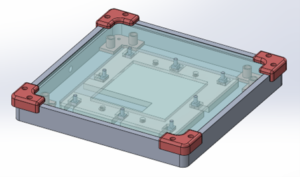

Description: The step trainer has been designed and manufactured to help aging populations and others with mobility issues to improve their reaction time to hazards. It lights up to tell a user to tap on it, tracking their reaction time so users and physical therapists can see improvements over time. It is designed to allow two step trainers to sync and run at the same time, giving users a variety of difficulty levels.

Description: The step trainer has been designed and manufactured to help aging populations and others with mobility issues to improve their reaction time to hazards. It lights up to tell a user to tap on it, tracking their reaction time so users and physical therapists can see improvements over time. It is designed to allow two step trainers to sync and run at the same time, giving users a variety of difficulty levels.

Team: Carson Martines, Yara Ahmed, Julia Metivier, Melissa Srey, Ellie Vail, Natalie Vu

Advisor: Dr. Erika Pliner

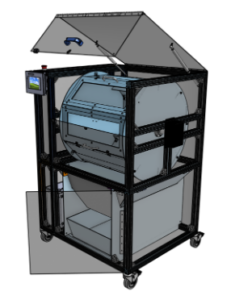

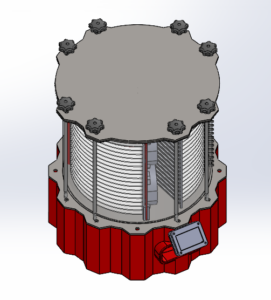

Description: L3Harris’s additive manufacturing lab uses an HP 5200 MJF 3D printer. This machine uses a thermo-chemical process to fuse nylon powder into 3D geometries. The process is layer-based – a thin layer of loose powder is spread over the print-bed and fused in select areas to create the part. As a result of this, unfused powder surrounds the produced parts. ‘Depowdering’ is the post processing step of removing the bulk unfused powder from the MJF printed parts so that they can be used. L3Harris currently performs part depowdering by hand, using brushes and vacuums. This process requires many hours of hands-on manual labor. So, they have tasked us with creating a machine that automates the depowdering post-processing step while also collecting the bulk powder for re-use.

Description: L3Harris’s additive manufacturing lab uses an HP 5200 MJF 3D printer. This machine uses a thermo-chemical process to fuse nylon powder into 3D geometries. The process is layer-based – a thin layer of loose powder is spread over the print-bed and fused in select areas to create the part. As a result of this, unfused powder surrounds the produced parts. ‘Depowdering’ is the post processing step of removing the bulk unfused powder from the MJF printed parts so that they can be used. L3Harris currently performs part depowdering by hand, using brushes and vacuums. This process requires many hours of hands-on manual labor. So, they have tasked us with creating a machine that automates the depowdering post-processing step while also collecting the bulk powder for re-use.

Team: Mary Clancy, Andrew Tolton, Kin Blandford, Ethan Carcas, Wyatt Jones, Colman Howes

Advisor: Dr Shuaihang Pan

Description: An air brake assembly is the centerpiece of our high powered rocket. We will be competing against 170 other colleges at the ESRA competition in Midland, Texas in June. Our air brake design will use PD control to keep the rocket’s final altitude as close as possible to the target of 10,000 ft above ground.

Description: An air brake assembly is the centerpiece of our high powered rocket. We will be competing against 170 other colleges at the ESRA competition in Midland, Texas in June. Our air brake design will use PD control to keep the rocket’s final altitude as close as possible to the target of 10,000 ft above ground.

Team: Bronson Wright, Blake Rhodes, Brian Hernando, Carson Brashear, Jason Zamora

Advisor: Dr Alex Novoselov

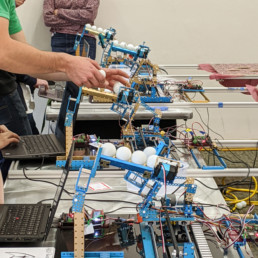

Description: Programmable Logic Controllers (PLC’s) are widely used in industrial applications to automate and control various processes. The University of Utah is developing a new industrial automation course that will teach students the foundations of PLC control in manufacturing processes. This project focuses on engineering a PLC training platform where students will learn control of the most common field devices found in industry without conforming to brand specific methodologies.

Description: Programmable Logic Controllers (PLC’s) are widely used in industrial applications to automate and control various processes. The University of Utah is developing a new industrial automation course that will teach students the foundations of PLC control in manufacturing processes. This project focuses on engineering a PLC training platform where students will learn control of the most common field devices found in industry without conforming to brand specific methodologies.

Team: Brandon Lim, Kelton McGrath, Shey Dilloway, Gavin Sueltz, Anthony Russo

Advisor: Dr Yongzhi Qu, Quinton Christensen

Description: The Baja SAE (Society of Automotive Engineers) competition is an annual collegiate engineering design competition where students design, build, and race single-seat, off-road vehicles. The competition simulates real-world engineering challenges by requiring teams to create a rugged, durable, and cost-effective vehicle that can handle rough terrain and extreme conditions. The Baja SAE Auxiliary Team is responsible for designing, optimizing, and integrating crucial support systems that enhance the performance, reliability, and serviceability of the Baja SAE off-road vehicle. The subsystems include braking, safety, fuel, paneling design, and engineering documentation as well as assisting the integration of the other teams’ responsibilities into a rule-abiding, competition-ready vehicle.

Description: The Baja SAE (Society of Automotive Engineers) competition is an annual collegiate engineering design competition where students design, build, and race single-seat, off-road vehicles. The competition simulates real-world engineering challenges by requiring teams to create a rugged, durable, and cost-effective vehicle that can handle rough terrain and extreme conditions. The Baja SAE Auxiliary Team is responsible for designing, optimizing, and integrating crucial support systems that enhance the performance, reliability, and serviceability of the Baja SAE off-road vehicle. The subsystems include braking, safety, fuel, paneling design, and engineering documentation as well as assisting the integration of the other teams’ responsibilities into a rule-abiding, competition-ready vehicle.

Team: Alex Felt, Daniel Dockstader, Sam Tremea, Christopher Pickett, Alvaro Mico Romero De Avila, Derek Madsen, Nolan Gagnon

Advisor: Randall Morrill, Andy Gill

Description: Our senior capstone project focuses on designing and building the powertrain for the University of Utah’s Baja SAE vehicle. The powertrain system is responsible for transmitting power from the engine to the wheels efficiently and reliably while withstanding the rigorous conditions of off-road racing. This project involves designing and integrating key components, including the transmission, driveshafts, differentials, and CV axles, to optimize performance, durability, and weight.

Description: Our senior capstone project focuses on designing and building the powertrain for the University of Utah’s Baja SAE vehicle. The powertrain system is responsible for transmitting power from the engine to the wheels efficiently and reliably while withstanding the rigorous conditions of off-road racing. This project involves designing and integrating key components, including the transmission, driveshafts, differentials, and CV axles, to optimize performance, durability, and weight.

Additionally, we must collaborate closely with the frame, suspension, and auxiliary teams to ensure seamless integration of the powertrain within the overall vehicle system. The final design must meet Baja SAE competition regulations and provide optimal power delivery while maintaining vehicle reliability across dynamic terrains. Through this project, we will apply engineering principles in mechanical design, dynamics, and manufacturing to develop a high-performance off-road powertrain solution.

Team: Ryan Tongue, Derek Williams, Jace Petersen, August Barnes, Mitch Bosgraaf, Brayden Paul

Advisor: Randall Morrill

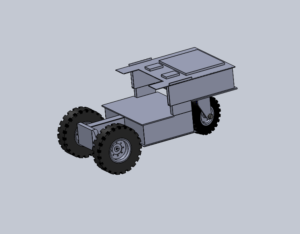

Description: The Useful Robot is a small, electric-powered construction machine designed for personal and light commercial use. The electric powertrain and hydraulic motors make the machine a sustainable and efficient alternative to traditional gas-powered equipment. The chassis consists of a steel frame where a modular arm connects to that allows different attachments for digging and lifting. It uses a custom hydraulic steering system for independent wheel control, enabling precise maneuverability and zero-turn movement. The steering system and attachments are connected through a custom hydraulic system that allows for quick connections and disconnections. The hydraulic system is controlled by an electrical system that manages the flow of the hydraulic fluid. The overall chassis is designed for use on dirt, grass, and concrete while handling slopes up to 30 degrees. With a maximum load of 2,500 lbs, a chassis weight of 2,500 lbs, and a top speed of 7 mph, the Useful Robot chassis is designed and built to be durable and adaptable for various applications.

Description: The Useful Robot is a small, electric-powered construction machine designed for personal and light commercial use. The electric powertrain and hydraulic motors make the machine a sustainable and efficient alternative to traditional gas-powered equipment. The chassis consists of a steel frame where a modular arm connects to that allows different attachments for digging and lifting. It uses a custom hydraulic steering system for independent wheel control, enabling precise maneuverability and zero-turn movement. The steering system and attachments are connected through a custom hydraulic system that allows for quick connections and disconnections. The hydraulic system is controlled by an electrical system that manages the flow of the hydraulic fluid. The overall chassis is designed for use on dirt, grass, and concrete while handling slopes up to 30 degrees. With a maximum load of 2,500 lbs, a chassis weight of 2,500 lbs, and a top speed of 7 mph, the Useful Robot chassis is designed and built to be durable and adaptable for various applications.

Team: Asael Horne, Brian Blackham, Manuel Ruiz, Quinton Jones, Trevor Stubbs

Advisor: Randal Morrill

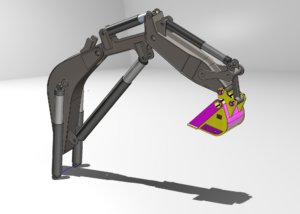

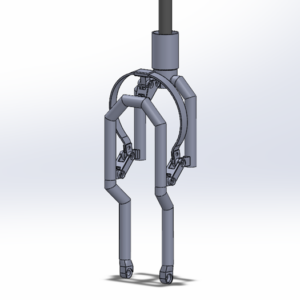

Description: The construction industry produces 37% of all greenhouse gas emissions. As a result, efforts have been made to reduce greenhouse gas emissions through the use of electric-powered machinery. The problem with current electric-powered machinery is that they only use one attachment and can only be used in a construction environment due to their size. The goal of our project is to design an arm attachment compatible with a chassis that can attach to both a forklift and an excavator bucket. The scope of our project is to design and simulate the full arm to ensure metrics are met, and to physically manufacture the boom and arm 1 subassemblies.

Description: The construction industry produces 37% of all greenhouse gas emissions. As a result, efforts have been made to reduce greenhouse gas emissions through the use of electric-powered machinery. The problem with current electric-powered machinery is that they only use one attachment and can only be used in a construction environment due to their size. The goal of our project is to design an arm attachment compatible with a chassis that can attach to both a forklift and an excavator bucket. The scope of our project is to design and simulate the full arm to ensure metrics are met, and to physically manufacture the boom and arm 1 subassemblies.

Team: Suhaani Shelat, Andrew Elliott, Luke Zhang, Faith Alba

Advisor: Randall Morrill

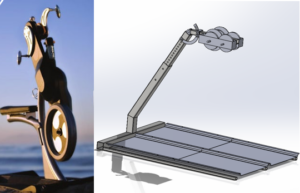

Description: A bike that uses hydraulics rather than a standard chain drive to move. The bike can change its drive modes between direct drive, boost and regenerative braking modes. Our team will race against other universities at a competition held by leading industry members of the hydraulic community.

Description: A bike that uses hydraulics rather than a standard chain drive to move. The bike can change its drive modes between direct drive, boost and regenerative braking modes. Our team will race against other universities at a competition held by leading industry members of the hydraulic community.

Team: Jon Dromey, Talon Rencher, Chris West, Cole Huseby, Johnathan Moriel, Johnny Vaughey

Advisor: Dr M Dillon

Description: The objective is to redesign and construct an exercise bike that will adapt to a wide range of spinal cord injuries and provide an effective experience for users.

Description: The objective is to redesign and construct an exercise bike that will adapt to a wide range of spinal cord injuries and provide an effective experience for users.

We will create an adjustable, compact, easy to set up exercise bike that is wheelchair accessible.

Team: Macy Moore, Elise Nielsen, Christopher Hon, Martin Desposorio

Advisor: Dr Pedro Huebner, Andy Gill

Description: Every day, numerous construction workers are struck by falling objects on worksites, ranging from small tools like hammers to heavy steel beams. Currently, workers primarily rely on verbal warnings from colleagues to avoid such hazards, a method that is often unreliable. To enhance safety on construction sites, the Falling Object Sensing Helmet has been developed. This innovative helmet utilizes a Doppler radar sensor alongside LED indicators and haptic feedback to provide real-time alerts when a falling object is detected, helping mitigate risks and protect workers from potential injuries.

Description: Every day, numerous construction workers are struck by falling objects on worksites, ranging from small tools like hammers to heavy steel beams. Currently, workers primarily rely on verbal warnings from colleagues to avoid such hazards, a method that is often unreliable. To enhance safety on construction sites, the Falling Object Sensing Helmet has been developed. This innovative helmet utilizes a Doppler radar sensor alongside LED indicators and haptic feedback to provide real-time alerts when a falling object is detected, helping mitigate risks and protect workers from potential injuries.

Team: Jonathan Clifton, Hyrum Coleman, Jessica Lopez, Cameron Monson, Sami Mower

Advisor: Dr. Erika Pliner

Description: Within the biking world, Gravel Bike racing is becoming a bigger and bigger sport. A big component of this sport and where a competitive edge could be extended, is making bikes capable of speeding through washboard and medium sized obstacles, without the forces generated by doing so being transmitted into the bikers.

Description: Within the biking world, Gravel Bike racing is becoming a bigger and bigger sport. A big component of this sport and where a competitive edge could be extended, is making bikes capable of speeding through washboard and medium sized obstacles, without the forces generated by doing so being transmitted into the bikers.

While many solutions already exist in the market, none are clear winners and all of them come with downsides. By using carbon fiber as our spring element, something few solutions currently do, we hope to leverage ENVE’s existing expertise and create a functional prototype that ENVE could further develop.

Team: Sam Allen, Skyler Chandler, Bryce Bennett, Taylor Hawkes

Advisor: Dr A.K. Balaji

Description: Quadruped robots are becoming increasingly common and could have a significant impact in many industries that require significant human labor including agriculture. However, they are either prohibitively expensive or locked down and cannot be modified. The general goal of this project is to build a quadruped robot that is cheaper and more open than the alternatives, using the Open Dynamic Robot Initiative as a base.

Description: Quadruped robots are becoming increasingly common and could have a significant impact in many industries that require significant human labor including agriculture. However, they are either prohibitively expensive or locked down and cannot be modified. The general goal of this project is to build a quadruped robot that is cheaper and more open than the alternatives, using the Open Dynamic Robot Initiative as a base.

Team: Jordan Raver, Kevin Nelson, Yang Yang, Austin Neff, Sam Spencer, Ben Siesser

Advisor: Dr Shad Roundy, Dr Kam Leang

Description: Feeder systems, for high-pressure thermal energy conversion processing units, require the usage of several sorting and processing steps to enable pumping the feed-input to the required pressure for an effective conversion. This project aims to create a system that can accept heterogeneous mixed waste and continuously feed the waste at high pressure to the thermal conversion system. The final device should accept pelletized plastic grades 4-6, ground tire rubber, and forest waste (sawdust). The output must provide a mixture pressurized to at least 300 PSI, achieving a temperature of 150 °C.

Description: Feeder systems, for high-pressure thermal energy conversion processing units, require the usage of several sorting and processing steps to enable pumping the feed-input to the required pressure for an effective conversion. This project aims to create a system that can accept heterogeneous mixed waste and continuously feed the waste at high pressure to the thermal conversion system. The final device should accept pelletized plastic grades 4-6, ground tire rubber, and forest waste (sawdust). The output must provide a mixture pressurized to at least 300 PSI, achieving a temperature of 150 °C.

Team: Tristan Leerhoff, Bryce Rundell, Keegan Benfield, Michaelis Linardakis, Nefi Palma, Stacy Lujan

Advisor: Dr. Robert Parker, Dr. Kevin Whitty

Description: Methane is one of the most potent greenhouse gases. To limit the effects of short-term climate change, it is necessary to reduce the amount of methane in the atmosphere. Current solutions burn methane at high concentrations, however, these technologies are unable to capture methane at low concentrations, which limits the amount of methane that can be removed. This lab-scale bioreactor aims to solve this problem by growing a strain of specially developed methane-eating bacteria, which can remove methane at low concentrations. When methane molecules are consumed by this bacteria, they produce a biomass that can be used as sustainable food for fisheries.

Description: Methane is one of the most potent greenhouse gases. To limit the effects of short-term climate change, it is necessary to reduce the amount of methane in the atmosphere. Current solutions burn methane at high concentrations, however, these technologies are unable to capture methane at low concentrations, which limits the amount of methane that can be removed. This lab-scale bioreactor aims to solve this problem by growing a strain of specially developed methane-eating bacteria, which can remove methane at low concentrations. When methane molecules are consumed by this bacteria, they produce a biomass that can be used as sustainable food for fisheries.

Team: Aidan McPherson, Teagan Matthews, Matt Witt, Tanner Burton, Chris Liu, Chandler Millar

Advisor: Dr. Christian Clavijo

Description: Speed climbing is a relatively new Olympic sport with no current publicly-available methods to accurately quantify athlete performance kinematics. This project aims to provide highly accurate quantitative feedback to optimize USA Climbing training regimes. Our method will likely lead to performance improvements of USA Climbing athletes in future Olympic Games.

Description: Speed climbing is a relatively new Olympic sport with no current publicly-available methods to accurately quantify athlete performance kinematics. This project aims to provide highly accurate quantitative feedback to optimize USA Climbing training regimes. Our method will likely lead to performance improvements of USA Climbing athletes in future Olympic Games.

Team: Liam Schenk, Ian Davidson, Justin Wallace, Aidan Wallace, Hayden Thomas, Carson Earl

Advisor: Dr Stephen Mascaro

How to Sponsor a Capstone Project:

Visit the Capstone section of our website for more details on sponsoring Capstone Projects.

Upcoming Design Days

Spring 2025: April 17

Fall 2025: December 2nd