Director of the Utah Tribology and Precision Engineering Laboratory, mechanical engineering associate professor Bart Raeymaekers and metallurgical engineering volunteer faculty member Anthony Sanders, received United States Patent US 9,872,772 B2, for their prosthetic joint. This prosthetic joint significantly improves the longevity of prosthetic hip implants. More than 200,000 total hip replacement surgeries are performed annually in the United States, with each implant typically lasting 10-15 years before needing replacement. This requires intense and invasive revision surgery, which can be hard on the patients. By increasing the longevity of the original implant, we are able to delay the need for a replacement surgery, and improve patient comfort.

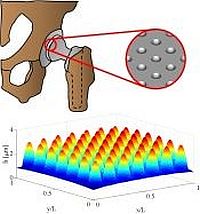

A hip implant consists of a Cobalt Chromium (CoCr) femoral head, anchored in the femur, which articulates with a polyethylene acetabular component that is implanted into the socket of the hipbone. Previous research in the Nanotribology and Precision Engineering lab, has demonstrated that adding a patterned microtexture to the CoCr head increases synovial lubricant film thickness when articulating with the polyethylene acetabular component. This increase in lubricant film thickness reduces contact between the two articulating components of the prosthetic hip implant, which reduces wear and increases longevity.

A hip implant consists of a Cobalt Chromium (CoCr) femoral head, anchored in the femur, which articulates with a polyethylene acetabular component that is implanted into the socket of the hipbone. Previous research in the Nanotribology and Precision Engineering lab, has demonstrated that adding a patterned microtexture to the CoCr head increases synovial lubricant film thickness when articulating with the polyethylene acetabular component. This increase in lubricant film thickness reduces contact between the two articulating components of the prosthetic hip implant, which reduces wear and increases longevity.